Garcia de Pou strengthens its strategy through intralogistics automation

GARCIA DE POU

Garcia de Pou, a pioneering company in Spain in the manufacture of single-use non-food products, which has the widest range of supplies for the hotel and catering industry, has completed the automation of its intralogistics process in the warehouse located in Ordis, with the help of ULMA Handling Systems.

The automation has enabled us to optimise and increase storage capacity, automate the picking of boxes with less rotation and improve picking time and capacity.

Requirements

In 1884, the couple Luis García and Francisca de Pou opened a printing press and a paper bag workshop, establishing the Garcia de Pou company, which has now been passed down through five generations.

The competitive strategy of the hotel and catering supplies manufacturer, Garcia de Pou, focuses on the broadness and depth of its catalogue, high stock availability and high speed order picking and delivery processes.

The automation of the Garcia de Pou warehouse located in Ordis derived from the need to increase its storage capacity by optimising the space available, to gain agility in the picking processes and to increase the capacity of the dispatch warehouse, as this was presented as a potential bottleneck.

Therefore, the intralogistic automation of its warehouse became a priority for the Garcia de Pou family business.

“The automation of both the warehouse processes and other areas of the company are a must for Garcia de Pou. Its application results in an improvement in quality, a reduction in time and costs and this leads to an increase in customer satisfaction.”, said Gerard Caula, Director of Operations and Process Improvement at Garcia de Pou.

Proposed solution

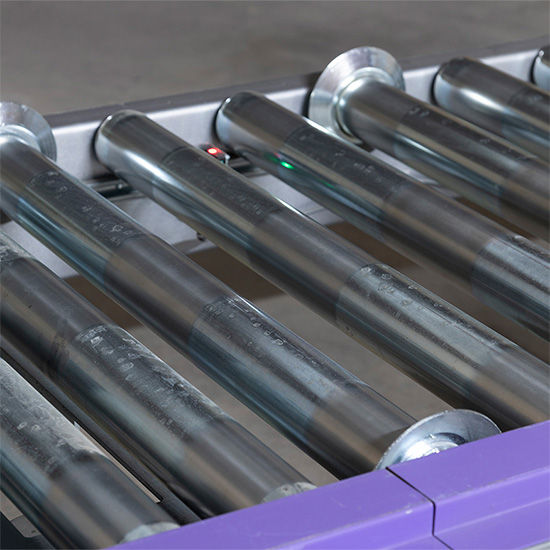

Garcia de Pou now has an intralogistics solution that serves all its customers in the most efficient way. ULMA Handling Systems has developed its intralogistics process, automating from the reception of the goods to their dispatch.

The automatic conveyor system receives hotel and catering supplies from its production centre and from other sources, which are sent to the self-supporting automated pallet warehouse. The automated warehouse is managed by 5 DAIFUKU Unit Load stacker cranes, and has a capacity of more than 22,000 pallets.

Garcia de Pou has different picking stations under the Product to Person concept, to ensure the picking is performed efficiently, followed by their consolidation and dispatch.

Result

The intralogistics solution developed at the Garcia de Pou facilities has made it possible to optimise storage space to the maximum and to increase productivity and efficiency in picking and dispatch. In addition, the facility allows for future expansion thanks to its flexible design.

“ULMA's team, its technology, as well as its extensive experience in multiple logistics projects, were important aspects in the decision. They quickly understood our needs, supporting us and giving us recommendations from the pre-sales phase, presenting us with a detailed and competitive proposal that finally led us to choose ULMA as our logistics partner”, added the Director of Operations and Process Improvement, Gerard Caula. “The automation project has made it possible to achieve the objectives set in the scope definition. We have managed to improve the ratios of m3 picked/hour, average picking time and m3 stored/m2 of space”, concluded Gerard.

Talk to us

Do you want to improve your productivity and be more efficient in your logistics?

Request information