General industry

The pillars of the industrial sector have always been flexibility, efficiency, productivity, cost-effectiveness, ergonomics and quality, among others. Thanks to technology, industry has advanced and is now in the 4.0 era, an interconnected era, where logistics 4.0 plays an essential role in meeting all the sector’s demands.

The requirements of the industry of the future to be able to compete in the market are becoming increasingly more complex: precision, JIT and JIS strategies, cost-effectiveness, flexibility to meet the variations of dynamic demand and quality, among others.

Nowadays, small, medium-sized and large companies rely on automated intralogistics to benefit from Industry 4.0. Challenges in different areas of the industrial sector:

- Automotive: very tight delivery times with increasing product customisation (JIT and/or JIS) due to the paradigm shift from B2B to C2B.

- Chemical industry: Storage, picking and transport of sensitive products with specific characteristics.

- Paper industry: Optimised storage space and handling of bulky and heavy loads. Importance of personal safety and ergonomics.

- Mechanical engineering: Increasingly more complex value-chain processes and workplace ergonomics, among others.

- Other: storage optimisation, safe handling and transport of materials, order picking for distribution, inventory and stock control, productivity and much more.

ULMA Handling Systems offers intralogistics solutions guaranteeing maximum availability, with an adaptable and modular design, from fully automated systems to semi-automated solutions, and the u·mind Logistics Suite which provides real-time control, visibility and information on the installation from anywhere.

Trends in the industrial sector:

- Lean Manufacturing strategies in many industrial companies

- Need for high availability rates to be able to meet requirements

- Critical speed of material restocking on production lines

- Continuous need for production flexibility

- Importance of automation to control costly tasks in industrial processes, with increased ergonomics and safety

- Importance of data and information: Software in a 4.0 environment, an increasingly interconnected environment

The key to being able to meet the requirements lies in an interconnected global intralogistics solution for optimal performance, where intralogistics becomes an added value throughout the value chain. People, machines, systems and products, all connected.

What can we offer to improve your intralogistics system?

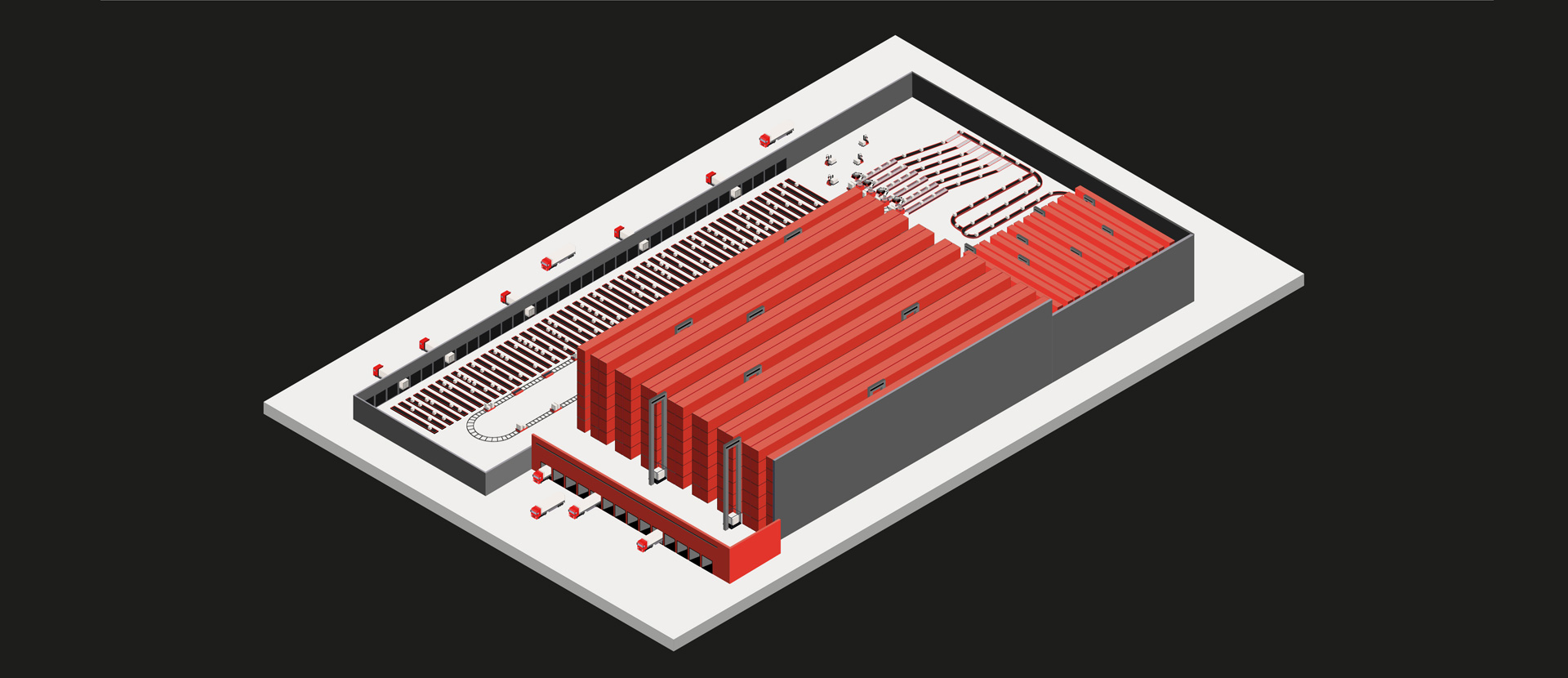

ULMA Handling Systems develops solutions where the industrial field takes a step further into the 4.0 era. Automated intralogistics solutions adapted to each company’s needs with the aim of optimising their processes: reception of material (from production or by truck), storage of goods, transport and handling, order picking and subsequent dispatch.

- Automated warehouses with materials stored in pallets, boxes or trays maximising process efficiency

- Fully automated or semi-automated solutions depending on each company's needs

- Capacity for future growth through scalable solutions

- Flexible order picking systems

- Safety and ergonomics in the workplace

- Robots for automated palletising and depalletising

- Automated transport systems: Sorting Transfer Vehicle (STV), Automated Guided Vehicles (AGV), among others.

- Suitable environments depending on the characteristics of the products to be stored.

- Thanks to the u·mind universe, the management will be simplified, optimised and have the required sophistication to help industrial companies in their management: connecting production and intralogistics

- Monitoring the installation in real time thanks to u·mind Sentinel

Solutions for the General industry sector

Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

- Automatic depalletising or ergonomic depalletising of goods, in accordance with intralogistics and system requirements

Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

Automated dry, temperature-controlled and/or frozen storage

Automated warehouse for large and bulky parts:

- Unit Load Stacker Crane

Automated warehouse for palletised products:

- Stacker crane: Unit Load

- Pallet shuttle

Automated warehouse for product in box or case:

Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: IK Pal robot and anthropomorphic robot, among others.

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

Shipping to customer

- Sorting for shipping (M-Shuttle, STV, Shuttle Cart, Crossbelt Sorter and much more)

- Output buffers (Unit Load and M-Shuttle)

U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

-

1. Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

- Automatic depalletising or ergonomic depalletising of goods, in accordance with intralogistics and system requirements

-

2. Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

-

3. Automated dry, temperature-controlled and/or frozen storage

Automated warehouse for large and bulky parts:

- Unit Load Stacker Crane

Automated warehouse for palletised products:

- Stacker crane: Unit Load

- Pallet shuttle

Automated warehouse for product in box or case:

-

4. Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: IK Pal robot and anthropomorphic robot, among others.

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

-

5. Shipping to customer

- Sorting for shipping (M-Shuttle, STV, Shuttle Cart, Crossbelt Sorter and much more)

- Output buffers (Unit Load and M-Shuttle)

-

6. U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

Discover our success stories

COSGRA

Cosgra improves order picking efficiency with mobile robotics

More information

SINTEPLAST

The Argentinian company Sinteplast doubles its picking capacity thanks to intralogistics automation

More information

GARCIA DE POU

Garcia de Pou strengthens its strategy through intralogistics automation

More information