Chemical and Pharmaceutical

The sensitivity of products in the pharmaceutical sector places high demands on the value chain, including the intralogistics process. Error elimination, product availability and fast and accurate delivery to customers are of great importance as they all have a direct impact on people's health.

Due to the sensitivity of pharmaceutical products, with inventory access control, temperature-controlled storage, product tracking and FEFO (First Expires, First Out) strategies, optimisation of processes throughout the value chain is key.

u·mind, ULMA's logistics suite, provides the control of stored products, guarantees traceability and offers real-time visibility and information.

Thanks to ULMA Handling Systems, the pharmaceutical sector can now have an automated storage solution combined with the technology and software adapted to its specific needs, thus optimising intralogistics flows. Process automation and standardisation ensure greater safety in all areas.

Trends in the pharmaceutical sector:

- Sensitive products requiring controlled access and special handling (temperature controlled)

- High quality requirements and importance of zero errors

- Maximum logistical traceability and inventory control

- Wide variety of products

- Sector with strict regulations in different areas of its value chain (GDP directive, among others)

- Complex product delivery requirements

- Increasing pressure to meet industry demands: consolidation between large wholesalers and retailers

ULMA Handling Systems’ intralogistics solutions and its extensive know-how in the pharmaceutical logistics chain guarantee the efficiency and precision required by the sector.

What can we offer to improve your intralogistics system?

Regardless of the nature of the business (manufacturing and/or distribution), ULMA Handling Systems adapts to the flow requirements with automated solutions thanks to its u·mind technology and software.

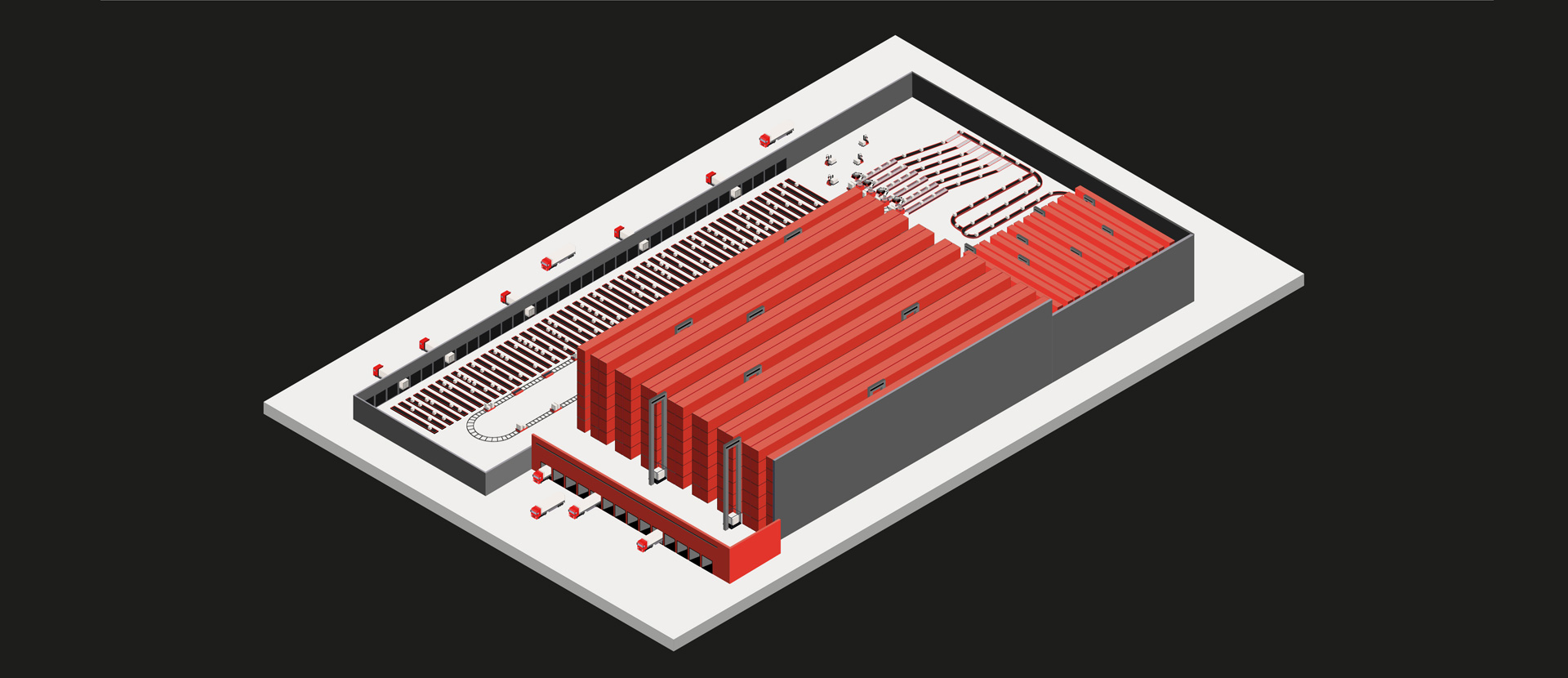

- Automated warehouses with pharmaceutical products in pallets, boxes or trays

- Specific temperature-controlled storage solutions

- “Product-to-Person” systems during the picking process

- Robots and automated guided vehicles (automatic transport)

- Ability to adapt to rapidly changing references (new products and/or changes in packaging) while maintaining the pace of logistics flows

- Ability to quickly identify batches if they are affected by anomalies or irregularities through traceability and inventory control

- Flexibility to adapt to changing regulations

- Thanks to the u·mind universe, the management will be simplified, optimised and have the required sophistication to help the pharmaceutical sector with inventory control, order picking, expiry date control and automatic early detection when expiry date is approaching, respecting FEFO models, etc.

Solutions for the Chemical and Pharmaceutical sector

Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

Automated dry, temperature-controlled and/or frozen storage

U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

Shipping to customer

- Sorting for shipping (STV, Shuttle Cart, light load conveyors and/or crossbelt sorter)

- Output buffers to maintain the cold chain (Unit Load, Mini Load, M-Shuttle, FSS-SQS and/or pallet shuttle)

Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: layer robot, IK Pal robot, anthropomorphic robot, unit picking robot, unstackers and box stackers, among others.

- Conveying light loads: descrambling, sorters, light load conveyors

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

-

1. Receipt of goods

- Receipt of goods from suppliers and/or production

- Goods quality check

-

2. Automated transport of goods to the warehouse:

- Pallet conveyors

- Automated Guided Vehicles or AGV

- Sorting Transfer Vehicles or STV

- Shuttle carts

-

3. Automated dry, temperature-controlled and/or frozen storage

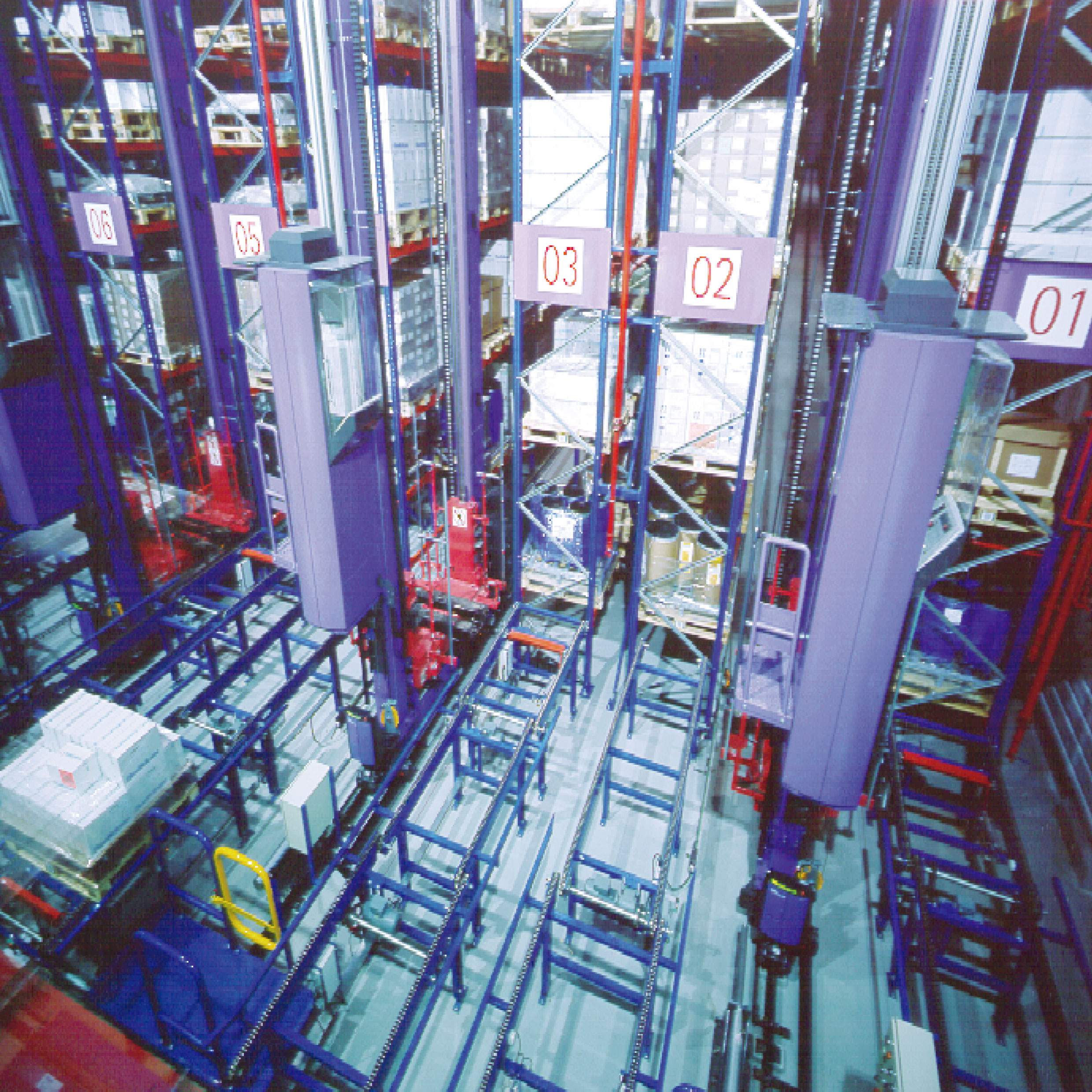

Automated warehouse for palletised pharmaceutical products/material:

- Stacker crane: Unit Load

Automated warehouse for pharmaceutical products/material in tray/box/case:

-

4. U-Mind, logistics suite (software) to manage, control and supervise the whole warehouse and distribution centre intralogistics process:

- Warehouse Management System (U·Mind WMS)

- Supervisory system (U·Mind Sentinel)

- and much more!

-

5. Shipping to customer

- Sorting for shipping (STV, Shuttle Cart, light load conveyors and/or crossbelt sorter)

- Output buffers to maintain the cold chain (Unit Load, Mini Load, M-Shuttle, FSS-SQS and/or pallet shuttle)

-

6. Efficiency and productivity in order picking

- Ergonomic depalletising and palletising stations: allow ergonomic assisted order picking of packages or load units

- Automatic palletising and depalletising: layer robot, IK Pal robot, anthropomorphic robot, unit picking robot, unstackers and box stackers, among others.

- Conveying light loads: descrambling, sorters, light load conveyors

- Goods to Person Solution: light load conveyors and crossbelt sorter, among others.

- Person to Goods Solution: Pick to Light and Picking Cart

Discover our success stories

GLAXOSMITHKLINE

Integral traceability system for improving the control of all the company’s production and distribution processes

More information

LILLY

Comprehensive automated logistics system

More information

D4 Logística & Distribución

Uruguay largest distributor of medicines, D4, is working at full capacity with ULMA's automated intralogistics solution

More information